A Grazmec utiliza cookies e outras tecnologias semelhantes para melhorar a sua experiência, de acordo com a nossa Política de Privacidade e, ao continuar navegando, você concorda com estas condições.

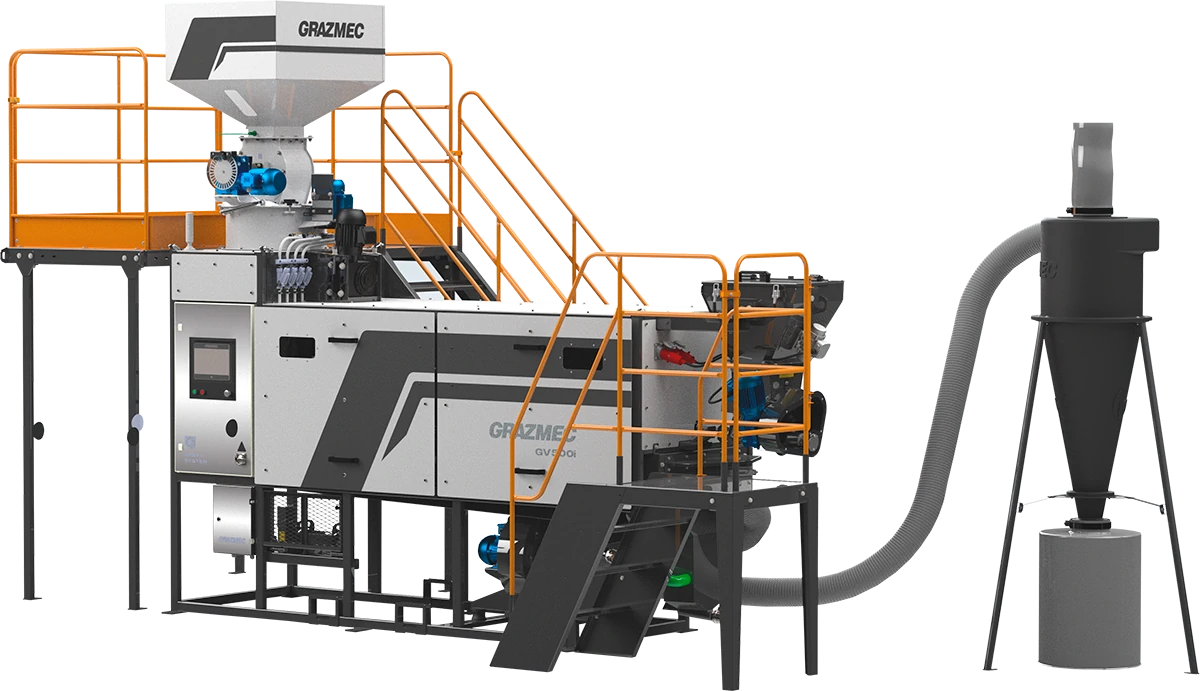

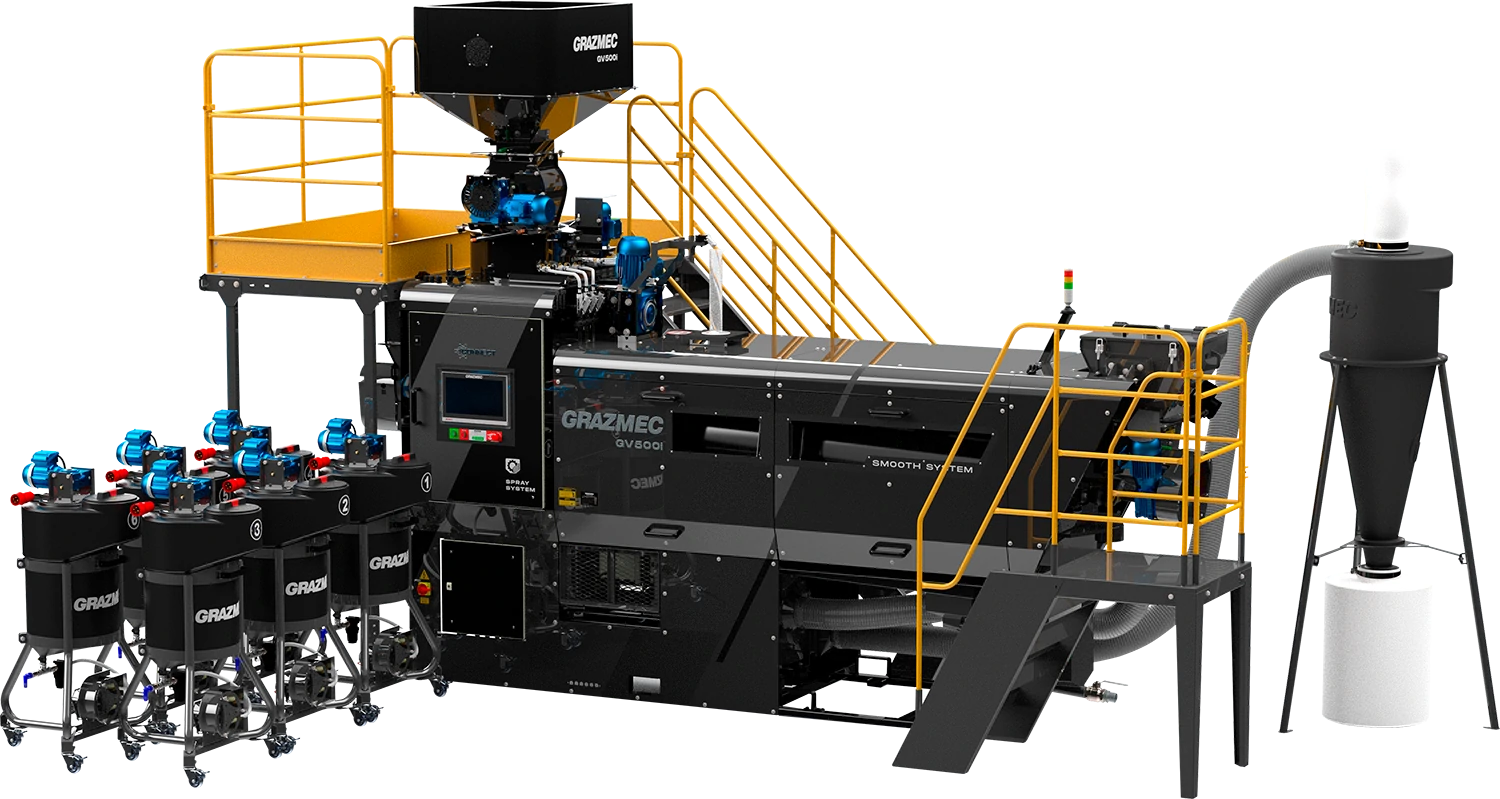

Treatment on Farm

Treatment Industrial

Agriculture

Storage

Classification

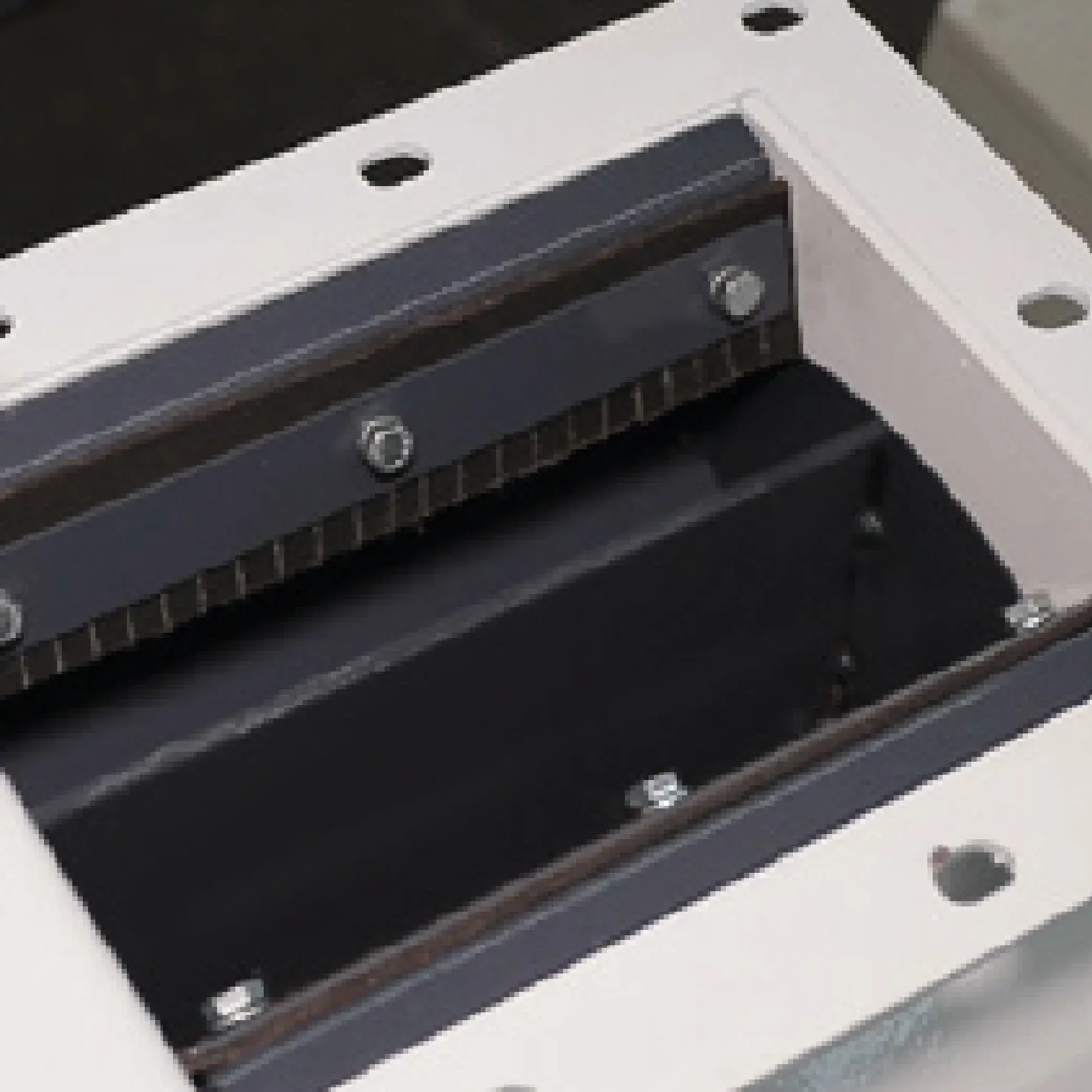

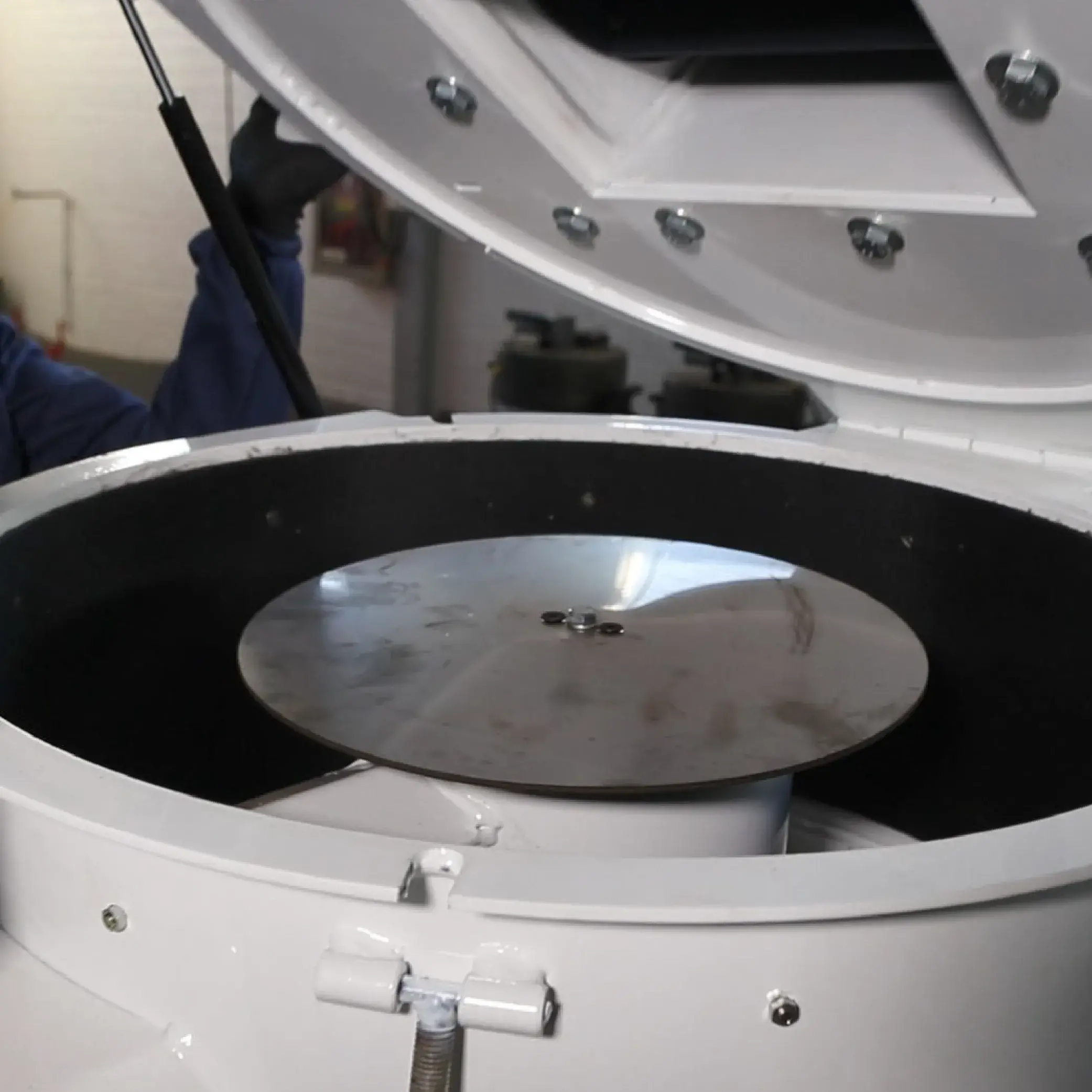

- The renowned Spray System treatment chamber, with a modern sluice that automatically supplies the continuous flow with the programmed amount of seed;

- Helicoid and internal details with rubberized coating, preserving the quality of the seed, i.e. there is no mechanical damage;

- Capacity of up to 180 Kg/min and yield of 10 t/h (soybeans, continuous flow);

- Lung silo and integrated sliding front platforms for easy movement of big bags. Structure compatible with the vast majority of forklift and wheel loader lifts in the field;

- Electronic dosing system (digital), simple to operate, which avoids operator contact with the products;

- Provides excellent homogenization, using precise dosages without generating waste via an exclusive flow-metric peristaltic pump;

- The system performs the dosage as programmed via touch screen, equalizing the weight of the seed with the volume of liquid mixture applied;

- Management software that stores the volume data of the products used;

- It has a login/password and saves up to 10 treatment recipes in the program;

- Mobile totem for digital control of the system makes the layout of the machine more flexible;

- Intelligent system that alerts the operator when the seed and/or fertilizer has reached the end of its supply, awaiting replenishment;

- Peristaltic pumps can be connected directly to the IBCs;

- It caters for all producers, with technology, precision and perfect treatment coverage. Ideal for UBS (Seed Processing Units);

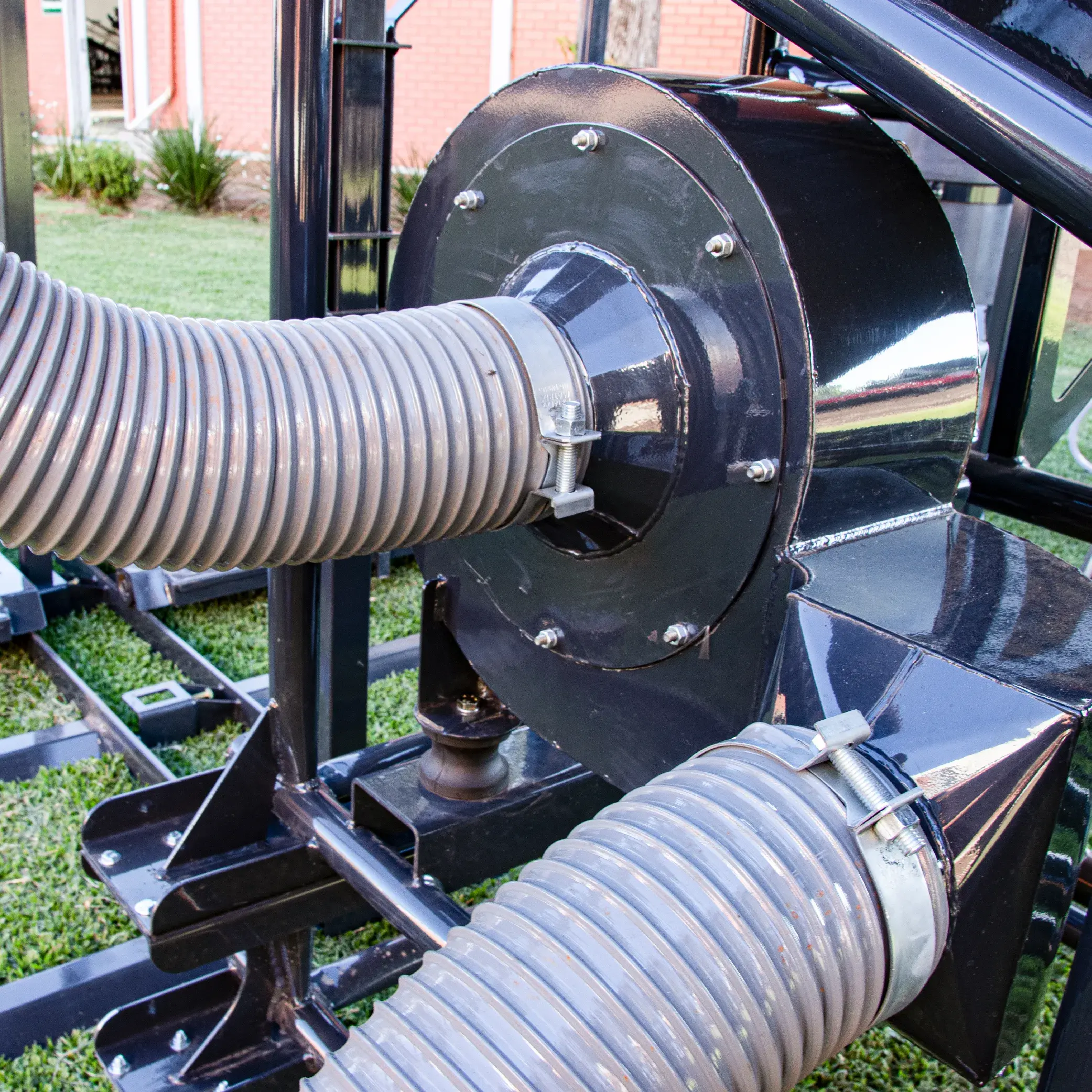

- Integrated dust collector system, including cyclone and bag filters;

- Complies with Safety Standard NBR 12.

COUPLED TO THE SPRAY SYSTEM TREATMENT CHAMBER

Total weight 1.920 kg

Total height 4,03 m

Lung silo supply height 3,57 m

Overall width 3,0 m

Total length 7,26 m

Treatment capacity 180 kg/min (10 t/h with continuous soybean flow)

Lung silo capacity 3 t (soya)

Liquid tank height 1,4 m

Liquid tank capacity 100 L (each)

Tipos de tratamento Liquids: inoculants, pesticides, fungicides, micronutrients Powders: drying agent, graphite, peat inoculant

Power supply Three-phase 380 Volts Frequency 60 Hz (optional 50 Hz for export)

Treatment system drive Digital (Touch Screen)

Seed metering sluice drive Three-phase 380 volts

Powder reservoir drive Electric geared motor 0.5CV

Seed metering sluice drive 1CV electric geared motor

Treatment chamber drive 1CV electric motor

Dust exhaust turbine drive 1CV electric motor

Homogenizing helicoid operation 2CV electric geared motor

Application of liquid products Treatment chamber

Application of powder products Helicoid conveyor

Optional 2nd powder reservoir, Stirrers for IBC, Hopper for 120 kg/soybean

Standard items 04 polyethylene liquid tanks, 01 powder tank, 01 seed dosing sluice, 01 lung silo with ladder and platform, 01 Front Kit for 02 big bags

![GV 240i [Connect] Effect](https://www.grazmec.com.br/images/gray-effetct-for-top.svg)

![GV 240i [Connect] Effect](https://www.grazmec.com.br/images/gray-effetct-for-top.svg)

Product Line Grazmec