A Grazmec utiliza cookies e outras tecnologias semelhantes para melhorar a sua experiência, de acordo com a nossa Política de Privacidade e, ao continuar navegando, você concorda com estas condições.

Treatment on Farm

Treatment Industrial

Agriculture

Storage

Classification

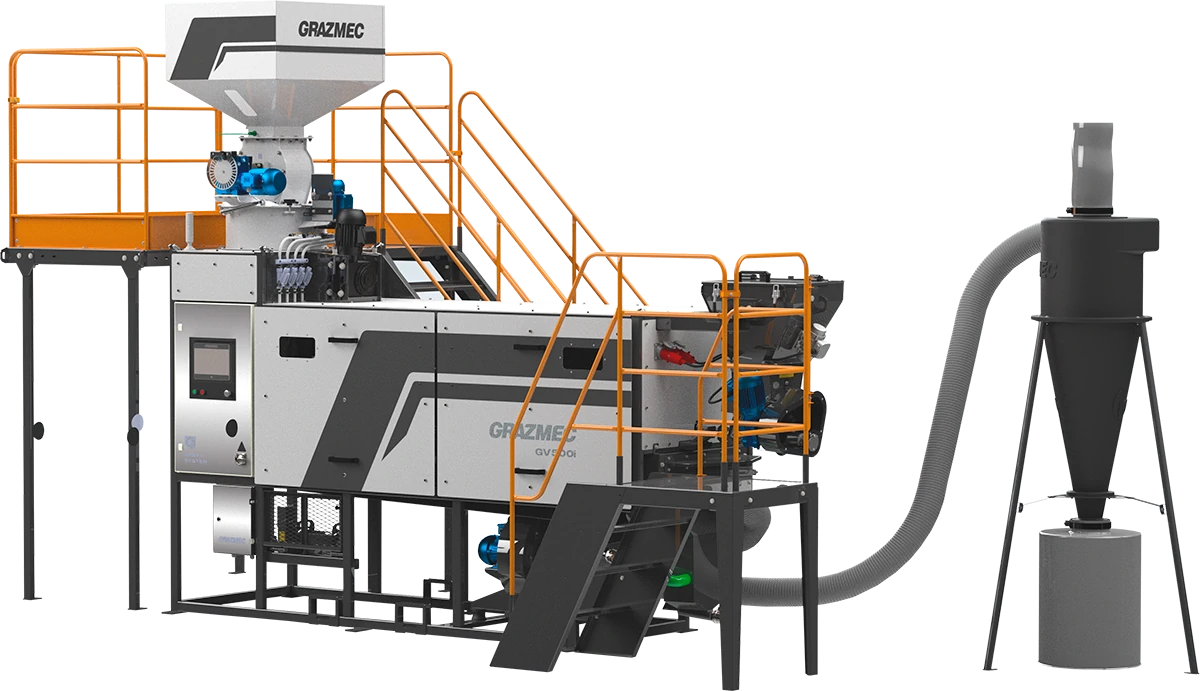

Design Award winner (silver category) at the BDA 2019 - Brasil Design Awards

New software with new configuration possibilities and data generation in a new format for machine management.

Six (6) tanks with a capacity of 100 liters each.

Reservoir for graphite or drying powder with a capacity of 100 liters.

Micronized peat tank with a capacity of 80 liters.

All machine controls via touch screen.

Smooth system tunnel for mixing the seed.

Access platform for drying powder/graphite supply.

Inoculant entry point option.

SERIAL ITEMS

06 polyethylene tanks for liquids

01 reservoir for drying powder or graphite

01 reservoir for peat inoculant

01 applicator for liquid inoculant

01 sluice

01 inspection platform with ladder

01 dust collection system

Treatment chamber, homogenization chamber and other seed contact and treatment components made of stainless steel.

![Treatment [Industrial] GV 500i [Connect]](https://www.grazmec.com.br/produto/imagem-destaque/1689298751-banner-webp.webp)

Weight 3.350 kg

Height 3,6 m

Width 2,8 m

Length 6,0 m

Treatment capacity Up to 500 kg/min (30 t/h with continuous flow)

Types of treatment LIQUIDS: inoculants, pesticides, fungicides, micronutrients. POWDER: Drying powder, graphite, peat inoculant.

Liquid tank height 1,49 m

Liquid tank capacity 100 L

Actuating the liquid tank stirrer 1/3CV geared motor

Treatment system drive Digital (Touch Screen)

Operating the treatment chamber 1CV electric motor

Operating the grain dosing sluice 1CV electric geared motor

Homogenizer tunnel drive 3CV electric geared motor

Powder reservoir drive (Drying powder / Graphite) 1CV electric geared motor

Powder reservoir drive (Peat inoculant) 1CV electric geared motor

Application of liquid products 06 liquid reservoirs directly in the treatment chamber (the 6th can be directed to the inlet of the homogenizing tunnel)

Application of powder products Directly in the homogenizing tunnel

Power supply Three-phase 380 Volts

Frequency 60 Hz (opcional 50 Hz para exportação)

Optional Stirrer for IBC

OBSERVATIONS:

- The WEIGHT, HEIGHT, WIDTH and LENGTH data refer to the machine without options;

- The TREATMENT CAPACITY and GRID CAPACITY data refer to SOYBEANS. For other crops, this value varies (shape and specific weight).

![GV 500i [Connect] Effect](https://www.grazmec.com.br/images/gray-effetct-for-top.svg)

![GV 500i [Connect] Effect](https://www.grazmec.com.br/images/gray-effetct-for-top.svg)

Product Line Grazmec